3.1 Motor mounts + integrated hinges

Overview

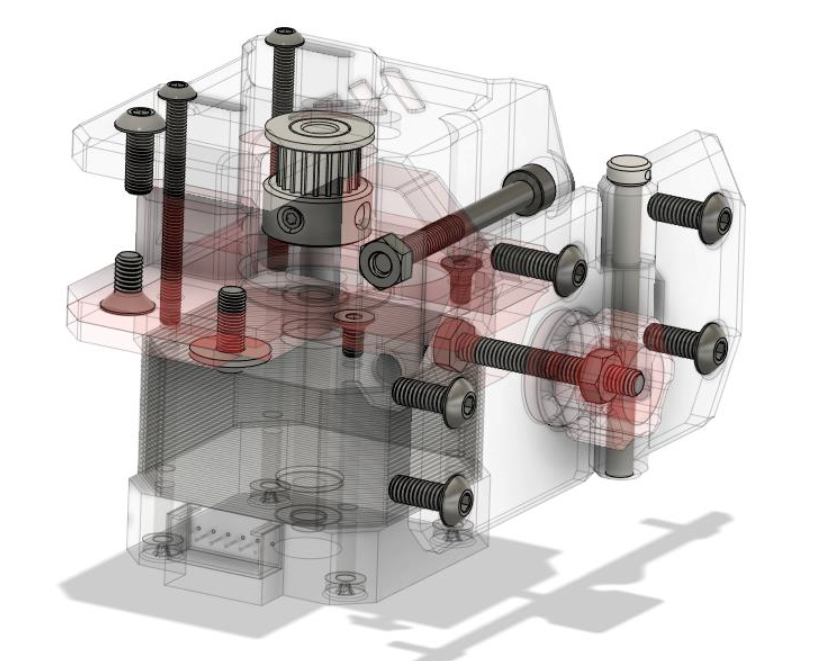

BOM

| Material | Quantity | Notes |

|---|---|---|

| M3 6mm (countersunk) | 6 | - |

| M3 35mm | 4 | - |

| M4 10mm | 12 | - |

| M4 8mm (countersunk) | 2 | - |

| M4 30mm (hex bolt) | 2 | - |

| M4 40mm (barrelhead) | 2 | - |

| M4 t-nut | 10 | - |

| M4 nut | 8 | (also, for hinges) |

| 4mm ID washer | 2 | - |

| NEMA 17 | 2 | - |

| GT2 20T Pulley | 2 | - |

STL’s

| File name | Amount to print |

|---|---|

| Motor mount Part A | Left + Right |

| Motor mount Part B | Left + Right |

| X tensioner | Left + Right |

| Tensioner knob | 2 |

| CAP | 2 |

| Integrated hinge | 2 |

| Hinge/motor reinforcement | Left + Right |

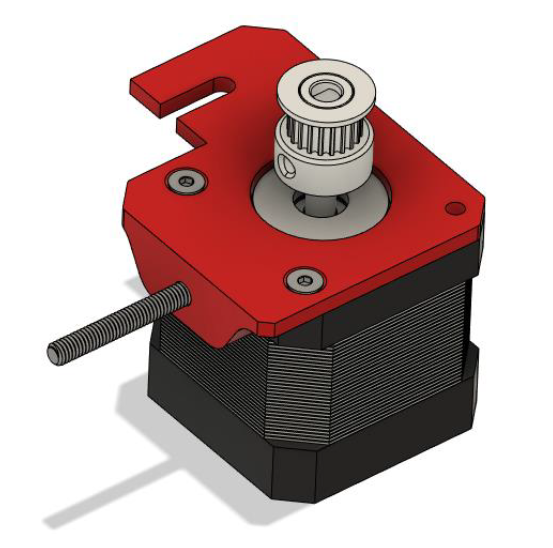

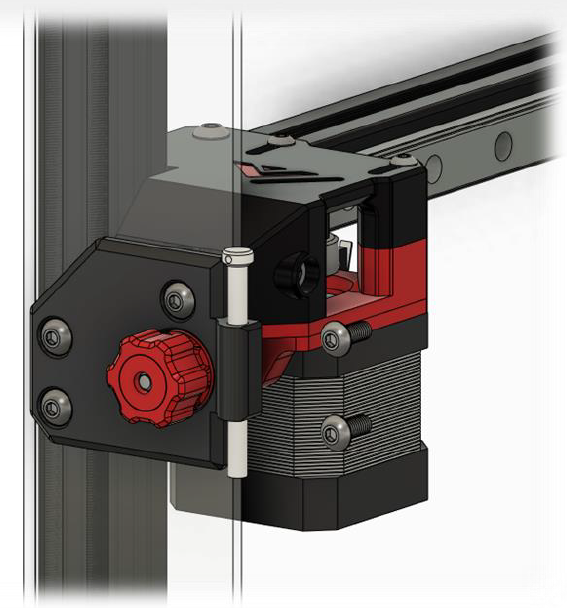

Step 1

First attach the printed tensioner to the motor like shown above

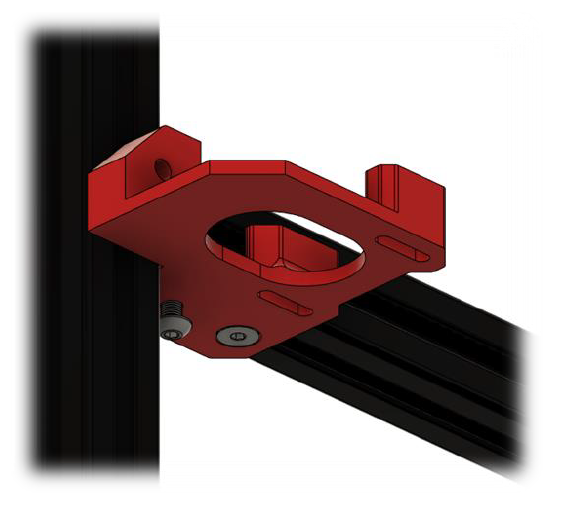

Step 2

Then attach the lower bracket of the motor mount to the frame

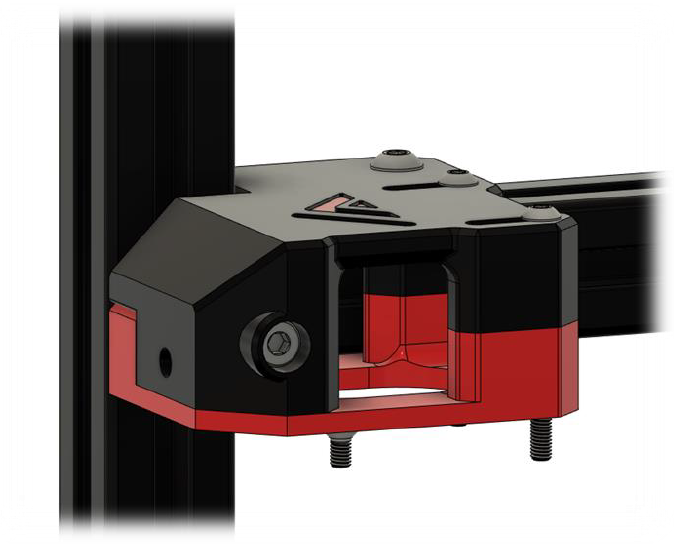

Step 3

Insert the M4 nut in the upper half of the motor mount and attach it on top of the lower mount and to the frame with M4 T-nuts. Don’t forget to tighten the two halves to the frame by screwing down the 40mm M4 into the printed M4 holder you inserted when assembling the frame.

Step 4

Attach the lowest part of the tensioner and motor, screw down the M4 in which the tensioner slides until it is snug, but the tensioner can still slide smoothly.

Step 5

Finally attach the small side panel piece and attach the front brace/integrated hinge and tensioner knob. The hinge and door assembly can also be installed now but for ease of working it is best to leave it off for now.

Step 6

Repeat for the other side