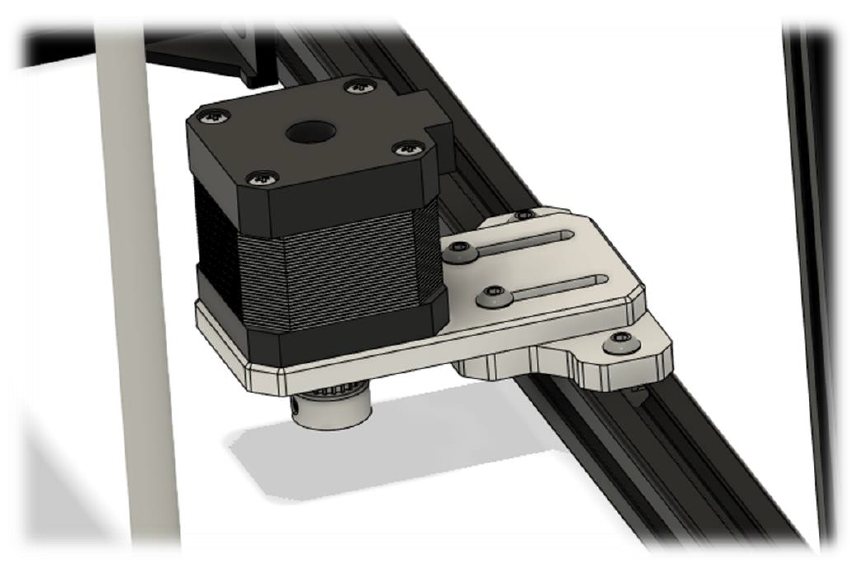

3.4 Z-Motor bracket

Parts

| Part | Location | Info |

|---|---|---|

| M3 x 10mm Quantity: 4 |

Layer: 3 Box: VZ330 Box 6 |

|

| M4 x 10mm Quantity: 4 |

Layer: 3 Box: VZ330 Box 6 |

|

| M4 x 12mm Quantity: 4 |

Layer: 3 Box: VZ330 Box 6 |

|

| M4 Washer Quantity: 2 |

Layer: 3 Box: VZ330 Box 6 |

|

| M4 t-nut Quantity: 2 |

Layer: 3 Box: VZ330 Box 6 |

|

| GT2 20 teeth Quantity: 1 |

Layer: 1 |  |

| NEMA 17 stepper Quantity: 1 |

Layer: 1 | |

| Motor mount plate Quantity: 1 |

Layer: 1 |  |

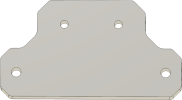

| Extrutsion mount plate Quantity: 1 |

Layer: 1 |  |

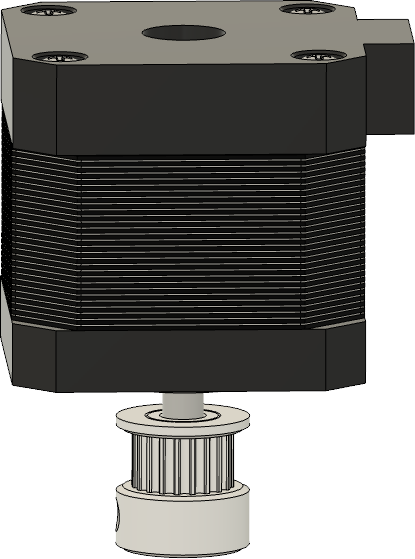

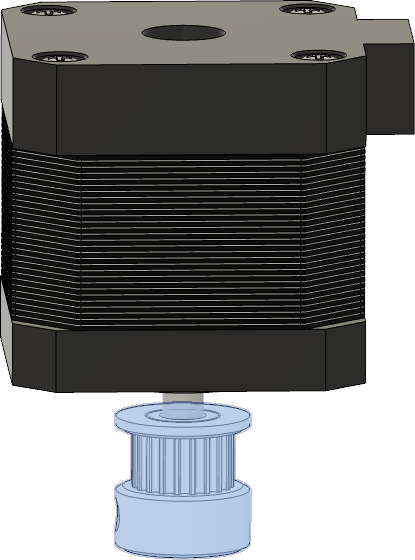

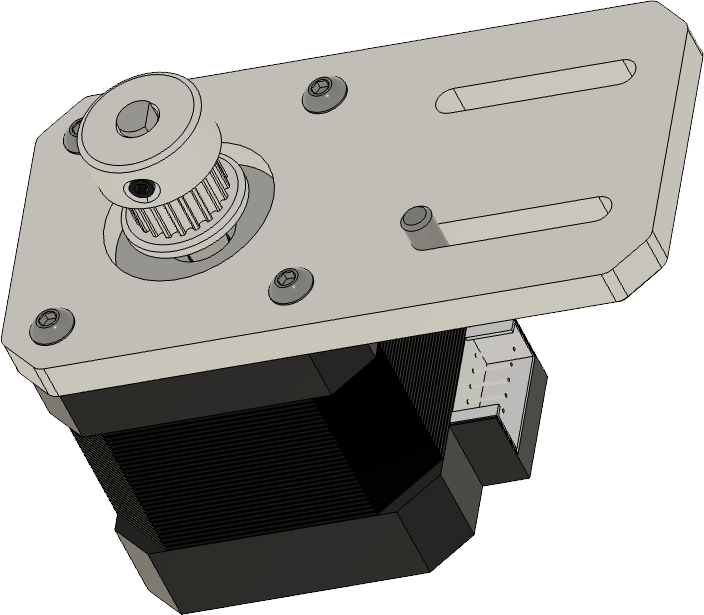

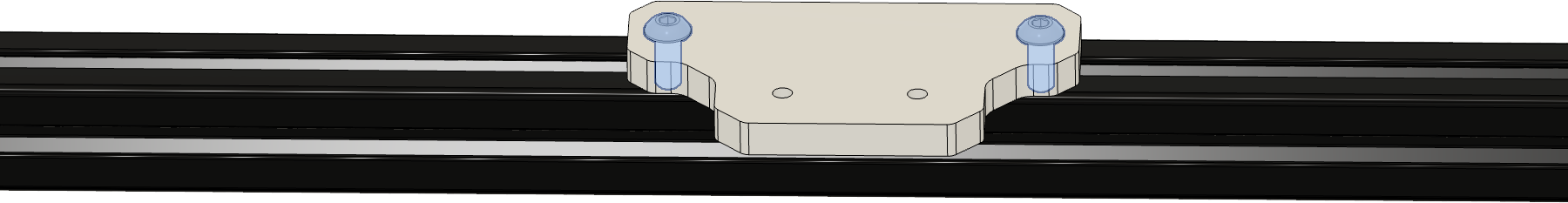

Step 1

|

| Part | Location |

|---|---|

| NEMA 17 motor Quantity: 1 |

Layer: 1 |

| GT2 20 teeth idler Quantity: 1 |

Layer: 1 |

|

• Attach the GT2 idler to the motor shaft of the nema 17 motor ( we will align it later ) |

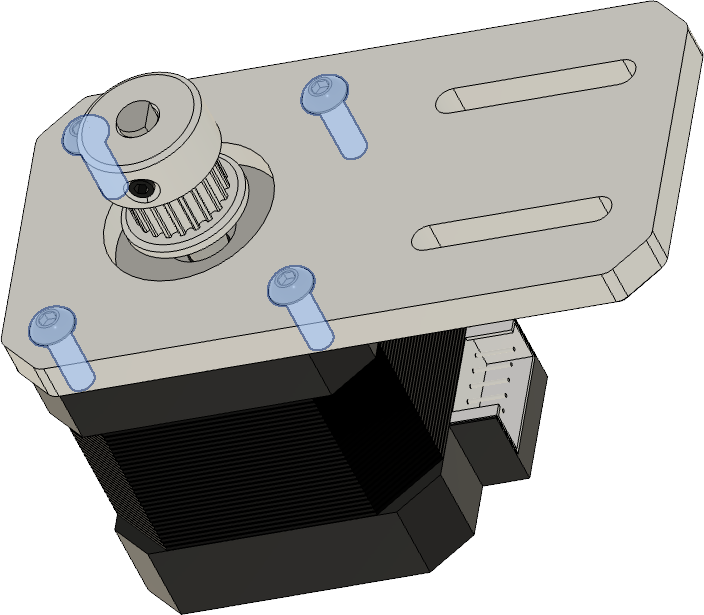

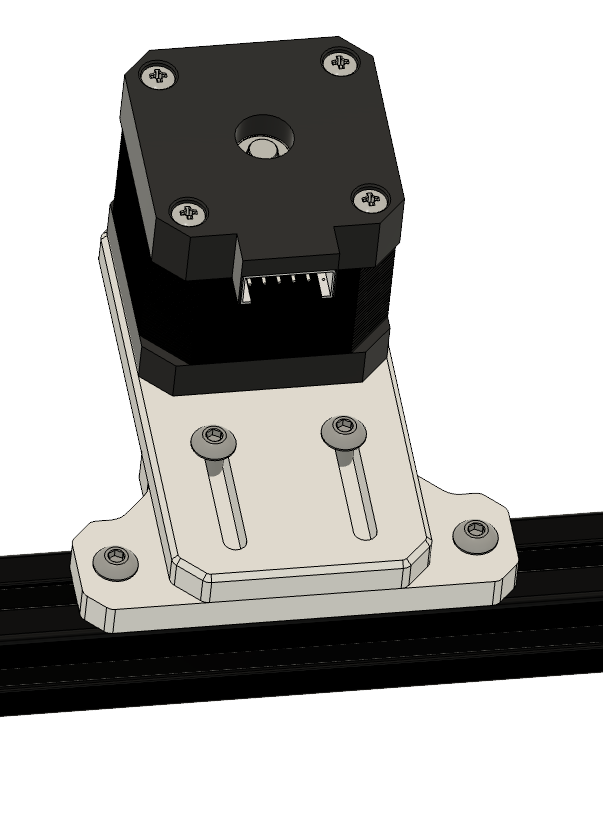

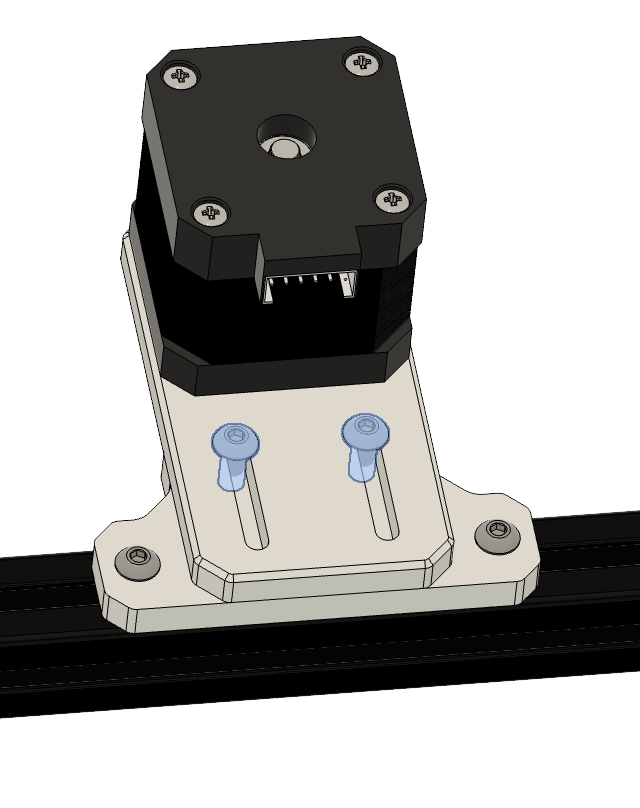

Step 2

Required

• Box 6 - M3 x 10mm

|

| Part | Location |

|---|---|

| NEMA 17 motor Quantity: 1 |

Layer: 1 |

| Motor mount plate Quantity: 1 |

Layer: 1 |

| M3 x 10mm Quantity: 4 |

Layer: 3 Box: VZ330 Box 6 Bag: M3 Bagnumber: 16/16 |

|

• Attach the NEMA 17 motor to the motor mount plate with the four M3 x 10mm screws. The chamfered side of the plate goes to the motor. • Take care that the motor cable points to the back ( the side with the slides in the plate). |

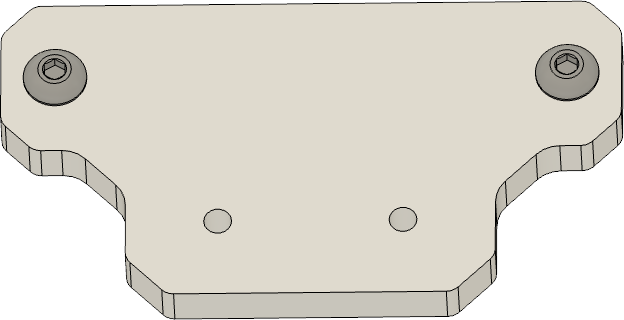

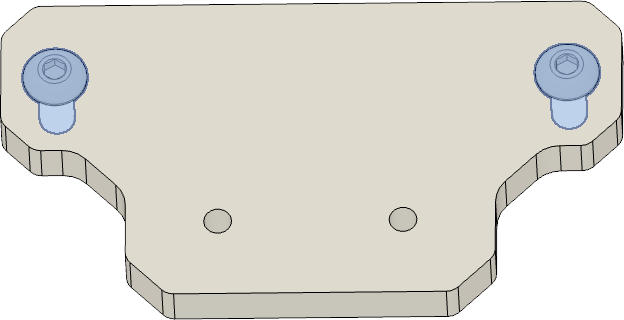

Step 3

Required

• Box 6 - M4 x 10mm

• Box 6 - M4 t-nut

|

| Part | Location |

|---|---|

| Extrutsion mount plate Quantity: 1 |

Layer: 1 |

| M4 x 10mm Quantity: 2 |

Layer: 3 Box: VZ330 Box 6 Bag: M4 Bagnumber: 14/16 |

| M4 t-nut Quantity: 2 |

Layer: 3 Box: VZ330 Box 6 Bag: M4 Bagnumber: 2/16 |

|

• Attach the M4 x 10 mm screw and the M4 t-nut to the plate |

Step 4

|

| Part | Location |

|---|---|

| Extrusion mount plate Quantity: 1 |

Layer: 1 |

|

• Attach the extrusion mount plate to the frame ( take care it’s in the middle of the back extrusion ) |

Step 5

Required

• Box 6 - M4 x 12mm

• Box 6 - M4 Washers

|

| Part | Location |

|---|---|

| Assembled motor mount Quantity: 1 |

Part from step 2 |

| M4 x 12mm Quantity: 2 |

Layer: 3 Box: VZ330 Box 6 Bag: M4 Bagnumber: 14/16 |

| M4 Washers Quantity: 2 |

Layer: 3 Box: VZ330 Box 6 |

|

• Put the assembled mount on the extrusion plate and screw in the M4 x 12mm screws slightly |

Step 6

- Put on the z-belt and tighten the belt by pulling the motor back and fixate it with the slightly screwed in M4 x 12mm screws.

- Loose the GT2 grub screws and align the belt that it is horizontal and tighten the grub screws on the flat spots of the motor after.