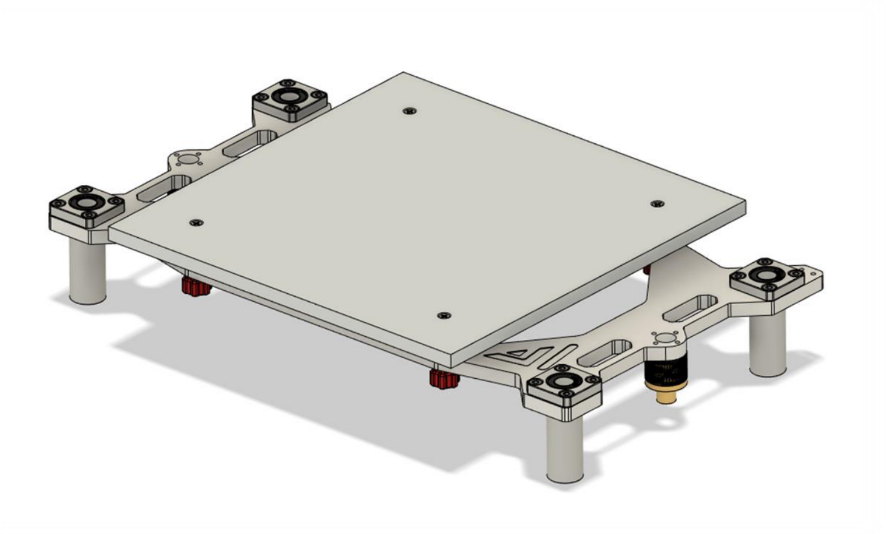

3.2 Bed Assembly

Parts

| Part | Location | Info |

|---|---|---|

| M3 x 10mm Quantity: 4 |

Layer: 3 Box: VZ330 Box 6 |

|

| M3 x 45mm (countersunk) Quantity: 4 |

Layer: 3 Box: VZ330 Box 6 |

|

| M3 nut Quantity: 4 |

Layer: 3 Box: VZ330 Box 6 |

|

| M4 x 10mm Quantity: 16 |

Layer: 3 Box: VZ330 Box 6 |

|

| LMK10LUU Quantity: 4 |

Layer: 2 |  |

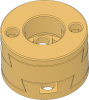

| Oldham coupler Quantity: 2 |

Layer: 2 |  |

| Springs / Silicon dumper Quantity: 4 |

Box: VZ330 Box 2 |

STLs

You can click on the object you wanna print on the plate and the corresponding STL will open up.

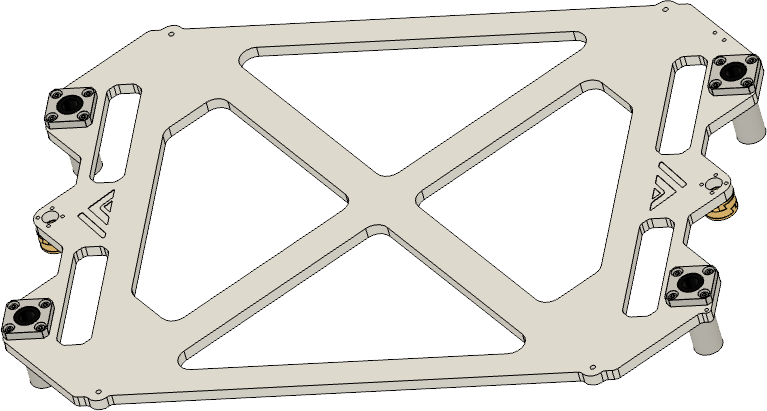

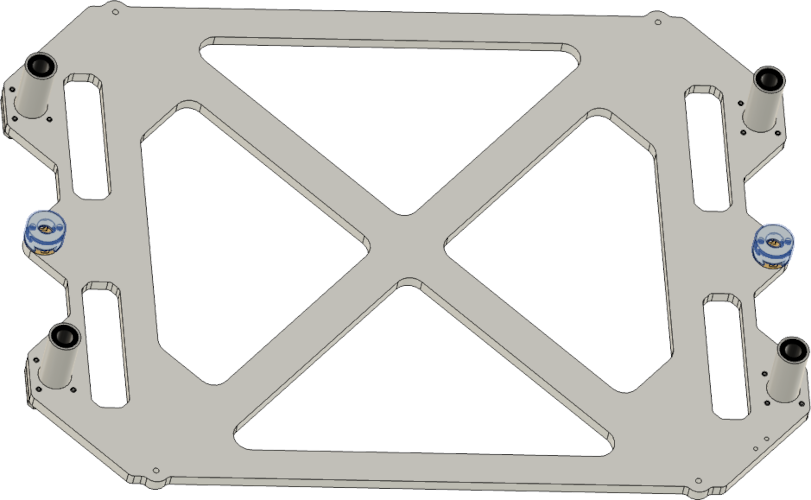

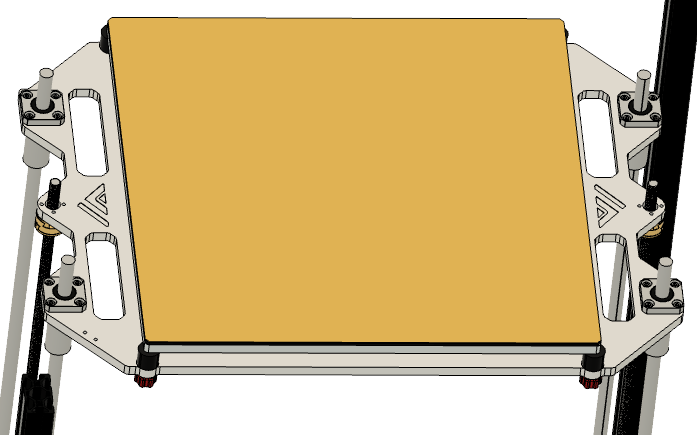

Step 1

Required

• Box 6 - M4 x 10mm

|

| Part | Location |

|---|---|

| Single bed piece Quantity: 1 |

Layer: 4 |

| LMK10LUU Quantity: 4 |

Layer: 1 |

| Oldham couplers Quantity: 2 |

Layer: 2 |

| M4 x 10mm Quantity: 16 |

Layer: 3 Box: VZ330 Box 6 Bag: M4 Bagnumber: 4/16 |

|:-|:-| |  | • Insert LMK10LUU in the four holes

• fixate them with the M4 x 10mm screws |

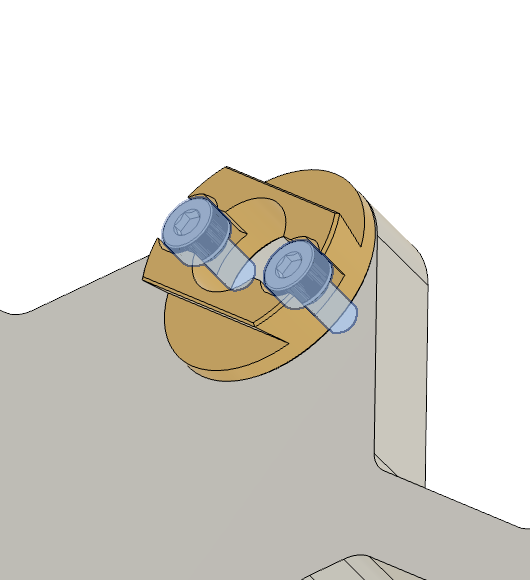

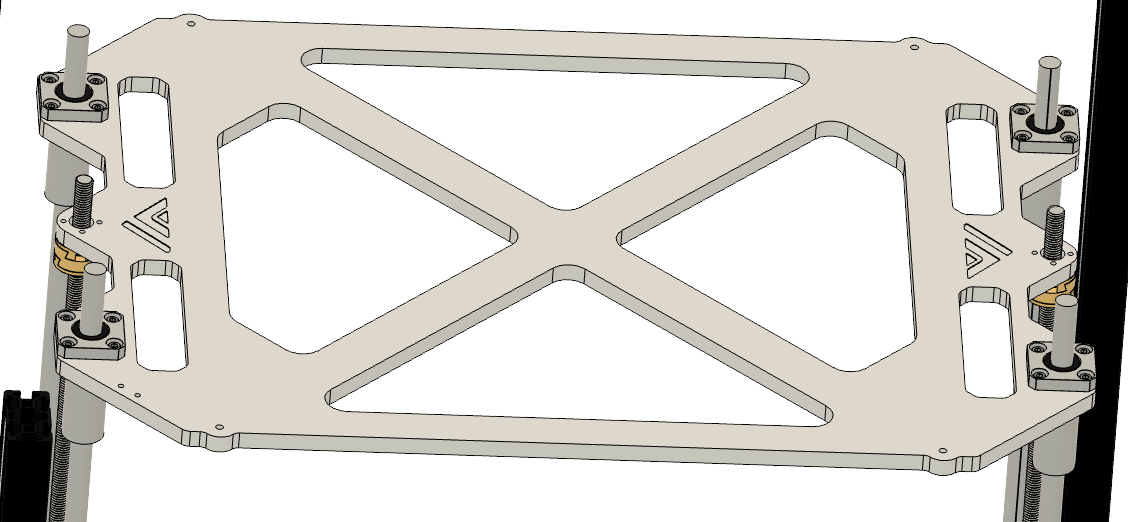

Step 2

Required

• Box 6 - M3 x 10mm

|

| Part | Location |

|---|---|

| Upper part of the oldham coupler Quantity: 2 |

Layer: 2 |

| M3 x 10mm Quantity: 4 |

Layer: 3 Box: VZ330 Box 6 |

|

• Attach the part of the oldham coupler to the center hole • Fixate it with the M3 x 10mm screw |

|

• Attach the rest of the oldham coupler to the fixated part |

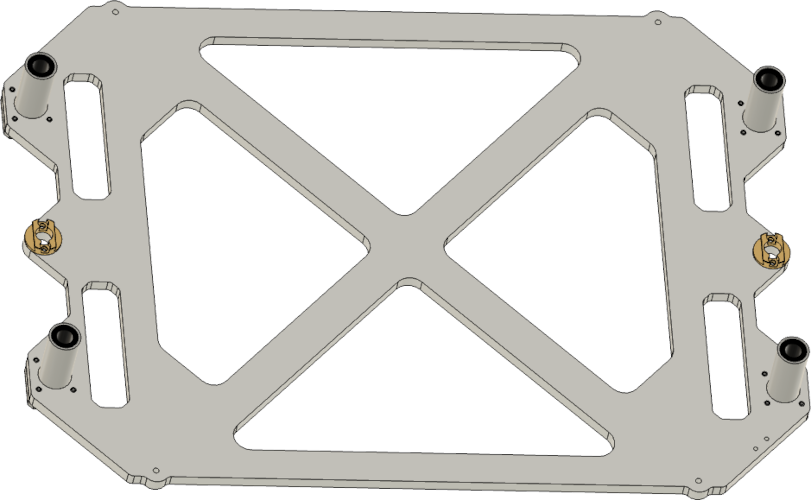

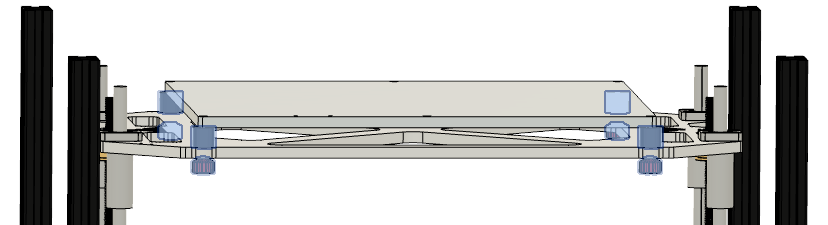

Step 3

|

| Part | Location |

|---|---|

| Assembled bed bracket Quantity: 1 |

Layer: 4 |

Pay attention when you assemble the bed the 2 small holes for the cable chain need to be on the right back where the motor with the tensioner is.

Instructions

|

• The part with the threaded hole needs to point to the back right • Slide the assembled bed bracket onto the rod’s • Screw in the leadscrew to the assembled oldham coupler |

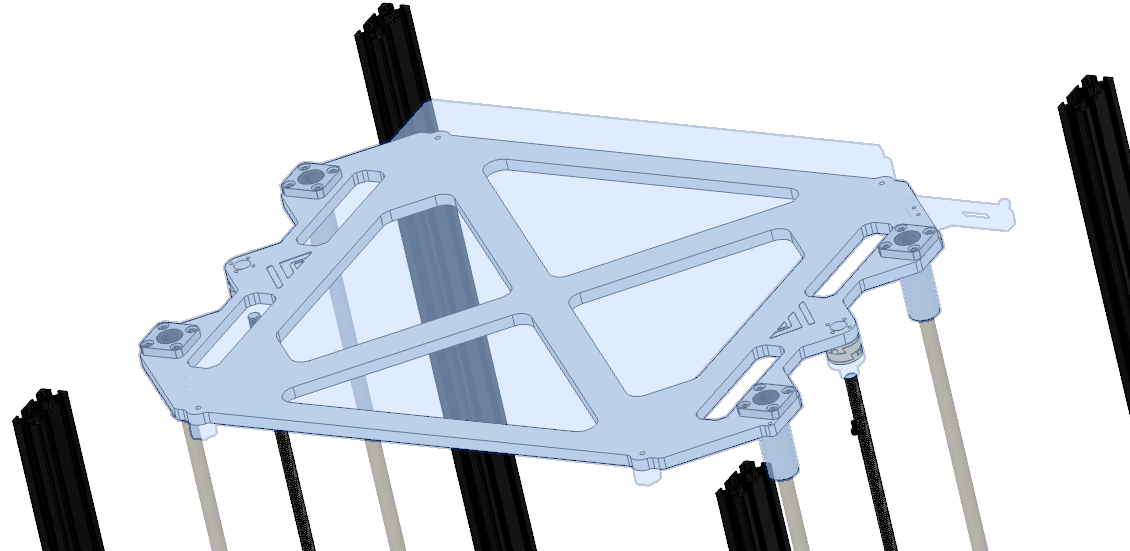

Step 4

| Part | Location |

|---|---|

| Aluminium Bed Quantity: 1 |

Layer: 4 |

| Heatbed Quantity: 1 |

Layer: 4 |

| Magnetic sheet Quantity: 1 |

Layer: 4 |

You should first apply the magnetic sheet and then the heated bed, due to the reason that the bed isn’t flat anymore after applying the heated bed due to the thermistor build into it.

Magnetic sheet

Heatbed

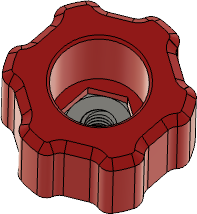

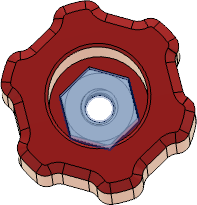

Step 5

Required

• Box 6 - M3 nut

|

| Bed leveling knobs Quantity: 4 |

STLs |

| M3 nut Quantity: 4 |

Layer: 3 Box: VZ330 Box 6 |

|

• Insert the m3 nut in the leveling knob and press it in so it sits flush at the bottom |

Step 6

Required

• Box 6 - M3 x 45mm

• Box 2

|

| Bed with attached heatmat and magnetic sheet Quantity: 1 |

Part from step 5 |

| M3 x 45mm Quantity: 4 |

Layer: 3 Box: VZ330 Box 6 |

| Spring’s or silicon dumper Quantity: 4 |

Box: VZ330 Box 2 |

| Bed leveling knob’s Quantity: 4 |

STLs |

|

• Put the silicon dumper’s or the springs on the 4 holes in the bed bracket • Put the assembled printbed ontop of the silicon dumpers or springs • Put the M3 x 45mm screws through the holes in the plate and secure them with the knobs from the bottom |