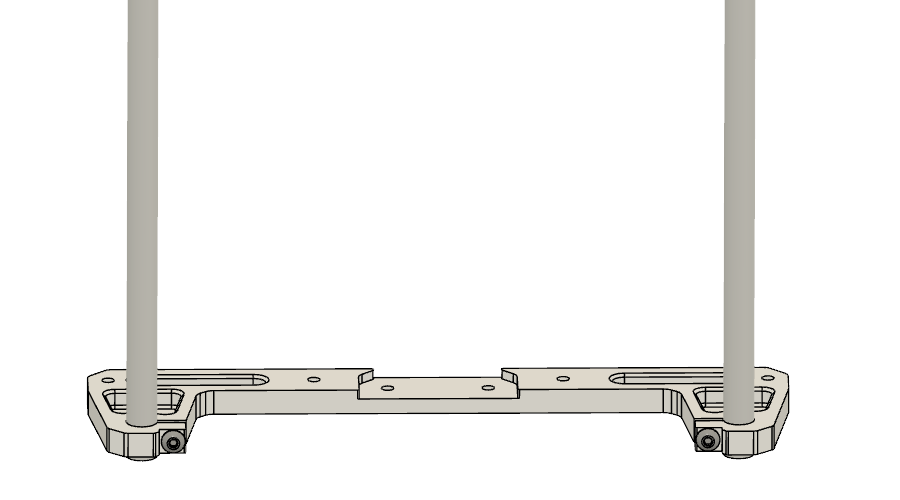

3.1 Lower rod & leadscrew bracket

|

Part’s

| Part | Location | Comment |

|---|---|---|

| M4 x 10mm Quantity: 4 |

Layer: 3 Box: VZ330 Box 6 |

|

| M4 x 12mm Quantity: 16 |

Layer: 3 Box: VZ330 Box 6 |

|

| M4 t-nut Quantity: 20 |

Layer: 3 Box: VZ330 Box 6 |

|

| M4 rollin t-nut Quantity: 4 |

Box: VZ330 Box 6 |  |

| 10mm rods ( 500mm ) Quantity: 4 |

Layer: 2 |  |

| Belt GT2 closed ( 1100mm ) Quantity: 1 |

Layer: 2 Box: VZ330 Box 2 |

picture |

| Leadscrew TR8 ( 500 mm ) Quantity: 2 |

Layer: 2 |  |

| GT2 40 teeth Quantity: 2 |

Layer: 2 Box: VZ330 Box 2 |

|

| z bracket Quantity: 2 |

Layer: 1 |  |

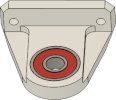

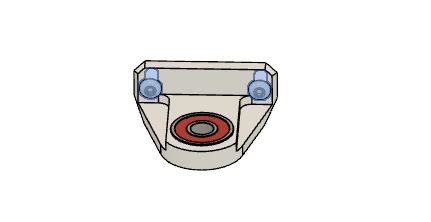

| Lower leadscrew mount Quantity: 2 |

Layer: 1 |  |

| Upper leadscrew mount Quantity: 2 |

Layer: 1 |  |

STL’s

You can click on the object you wanna print on the plate and the corresponding STL will open up.

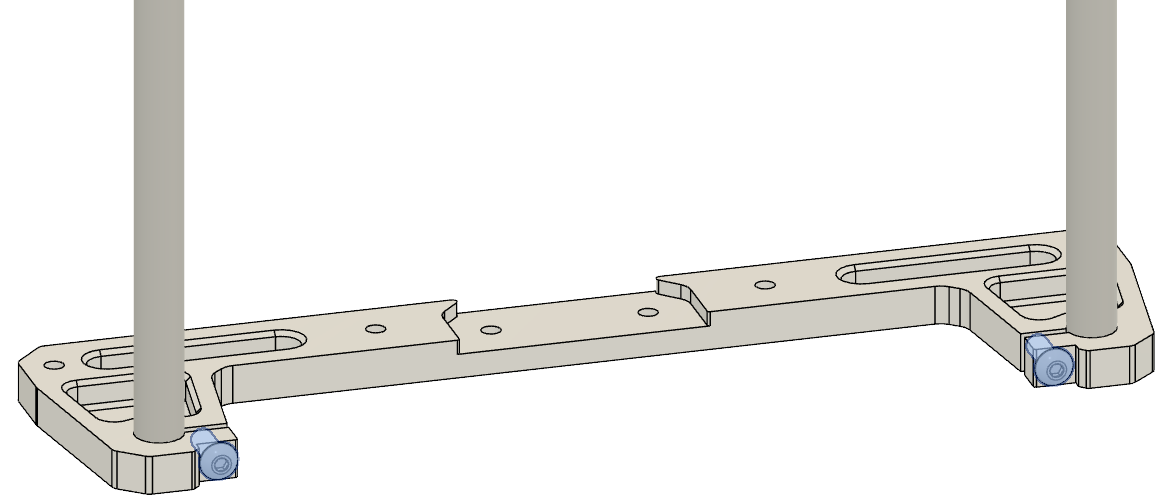

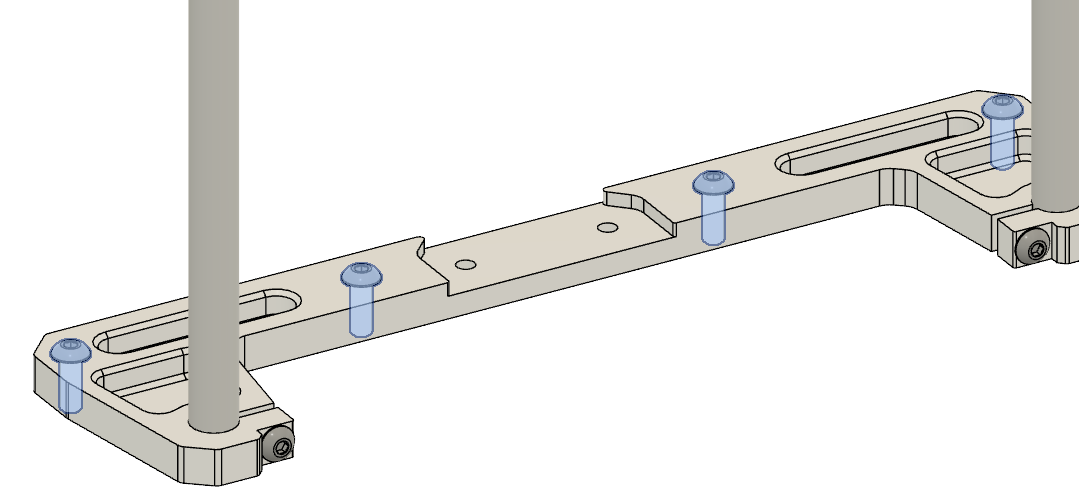

Step 1

Follow these instructions once for each side

Required

• Box 6 - M4 x 12mm

|

| Part | Location |

|---|---|

| z bracket Quantity: 2 |

Layer: 1 |

| M4 x 12mm Quantity: 4 |

Layer: 3 Box: VZ330 Box 6 Bag: M4 Bagnumber: 13/16 |

| Rods ( 10mm ) Quantity: 4 |

Layer: 1 |

|

• Align the rod flush with the bottom of the z bracket |

|

• Tighten the M4 x 12mm screw |

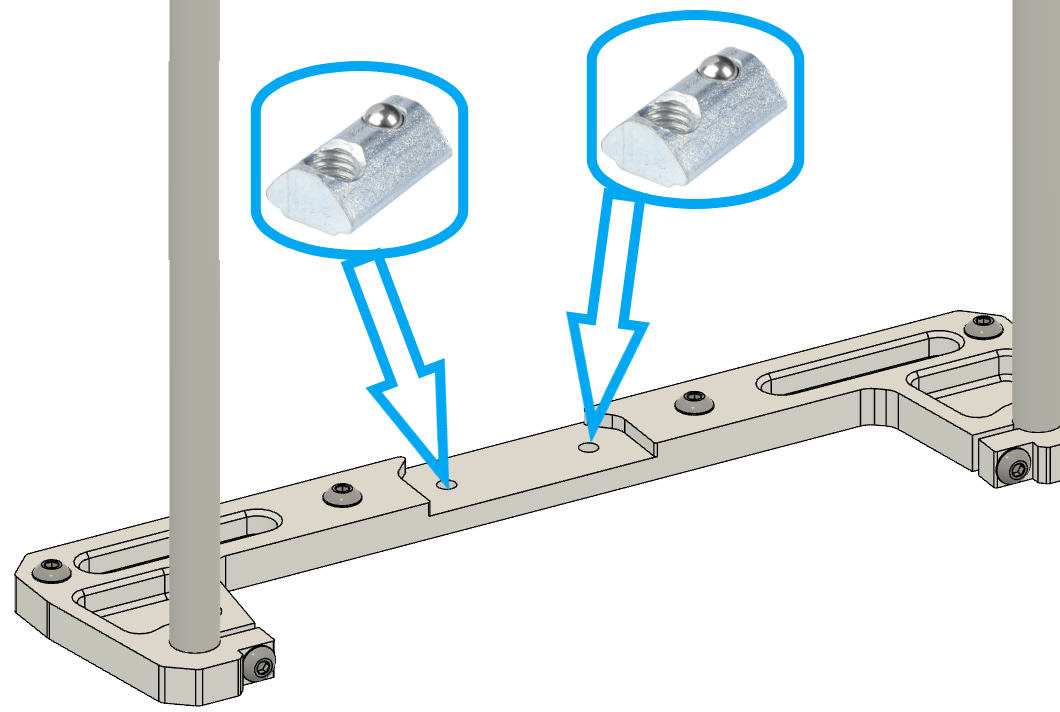

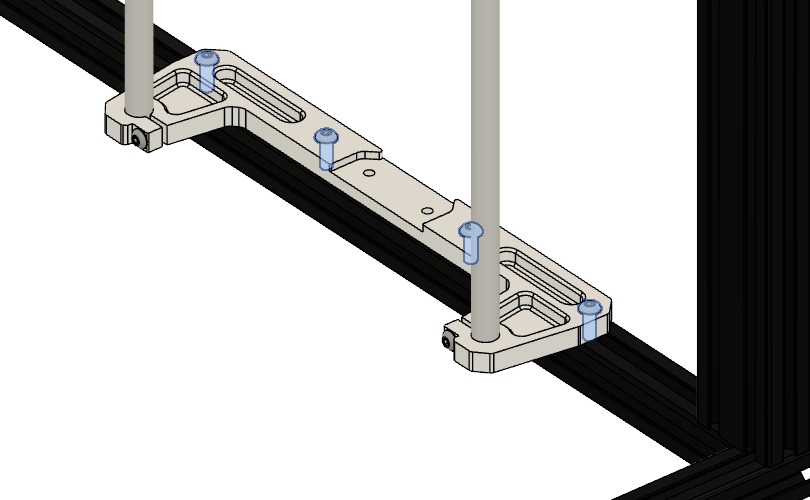

Step 2

Follow these instructions once for each side

Required

• Box 6 - M4 x 12mm

• Box 6 - M4 t-nut

• Box 6 - M4 rollin t-nut

|

| Part | Location |

|---|---|

| z bracket Quantity: 2 |

Layer: 1 |

| M4 x 12mm Quantity: 8 |

Layer: 3 Box: VZ330 Box 6 Bag: M4 Bagnumber: 13/16 |

| M4 t-nut Quantity: 8 |

Layer: 3 Box: VZ330 Box 6 Bag: M4 Bagnumber: 2/16 |

| M4 rollin t-nut Quantity: 4 |

Box: VZ330 Box 6 Bag: M4 Bagnumber: 3/16 |

|

• Insert rollin t-nut in the extrusion below the middle two holes |

|

• Attach M4 x 12mm + t-nut to the z bracket • Tip:Drop in the plate and add in the two screws for now in the two holes in the middle for the rollin t-nuts so they move with the part if you move it around. |

|

• Tighten the M4 x 12mm screw loosly, we need to align the z bracket |

|

• Align the front rod with the z-alignment tool. Use M4x10 and t-nuts for the tool. • tighten the M4 x 12mm screws, when it’s aligned |

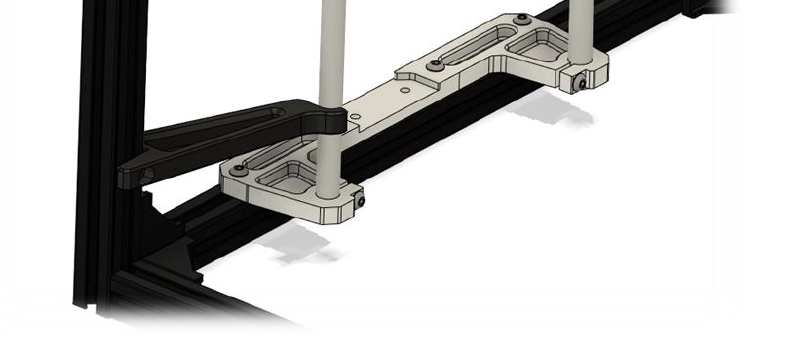

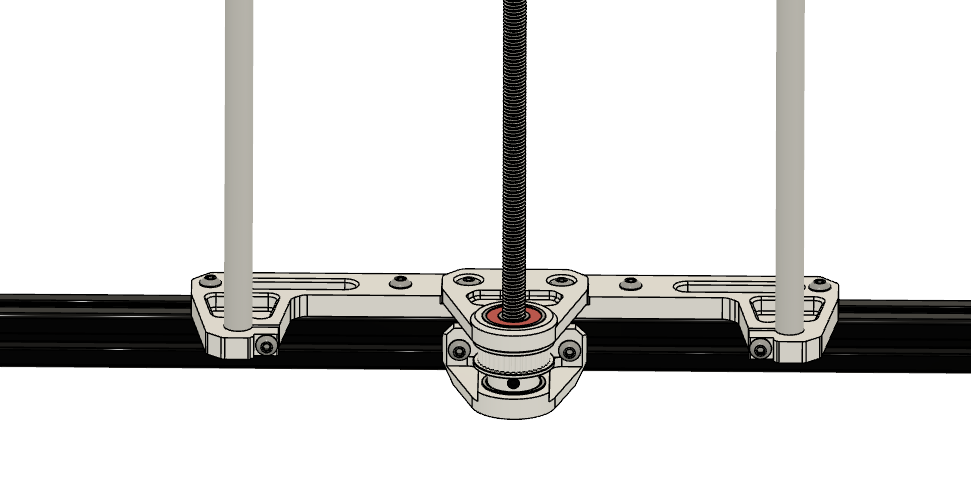

Step 3

Follow these instructions once for each side

Notes

Required

• Box 6 - M4 x 10mm

• Box 6 - M4 t-nut

|

| Part | Location |

|---|---|

| Lower leadscrew mount Quantity: 2 |

Layer: 1 |

| M4 x 10mm Quantity: 4 |

Layer: 3 Box: VZ330 Box 6 Bag: M4 Bagnumber: 13/16 |

| M4 t-nut Quantity: 4 |

Layer: 3 Box: VZ330 Box 6 Bag: M4 Bagnumber: 2/16 |

|

• Attach M4 x 10mm + t-nut to the lower leadscrew mount |

|

• Insert lower leadscrew mount to bottom extrusion • Tighten the M4 x 10mm screw loosly, and center the lower leadscrew mount • We will align the parts in Step 5 |

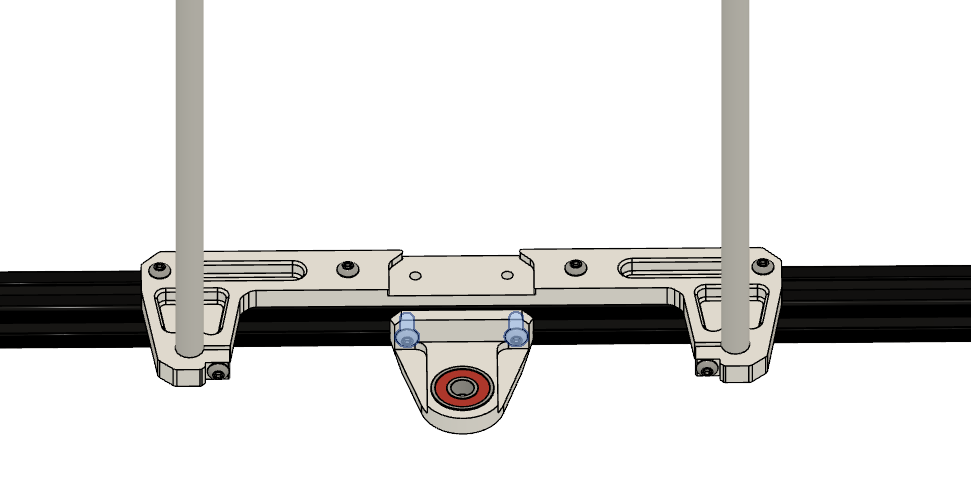

Step 4

Follow these instructions once for each side

Required

• Box 6 - M4 x 12mm

|

| Upper leadscrew mount Quantity: 2 |

Layer: 1 |

| M4 x 12mm Quantity: 4 |

Layer: 3 Box: VZ330 Box 6 Bag: M4 Bagnumber: 13/16 |

|

• Insert upper leadscrew mount to single z bracket • Tighten the M4 x 12mm screw loosly, and center the lower leadscrew mount • Use the leadscrews or a drill bit/similar tool (with 8mm diameter), put it through the two bearing’s and prealign the two mounts • We will align the parts in Step 5 |

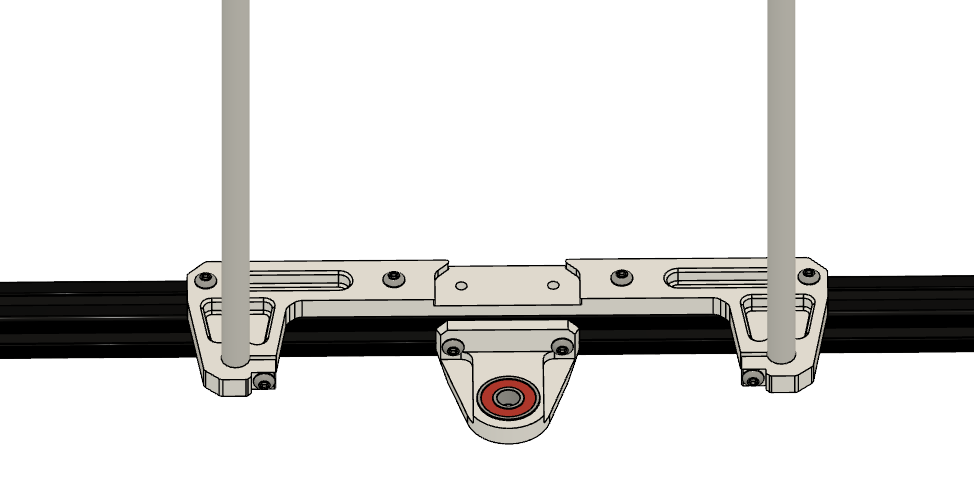

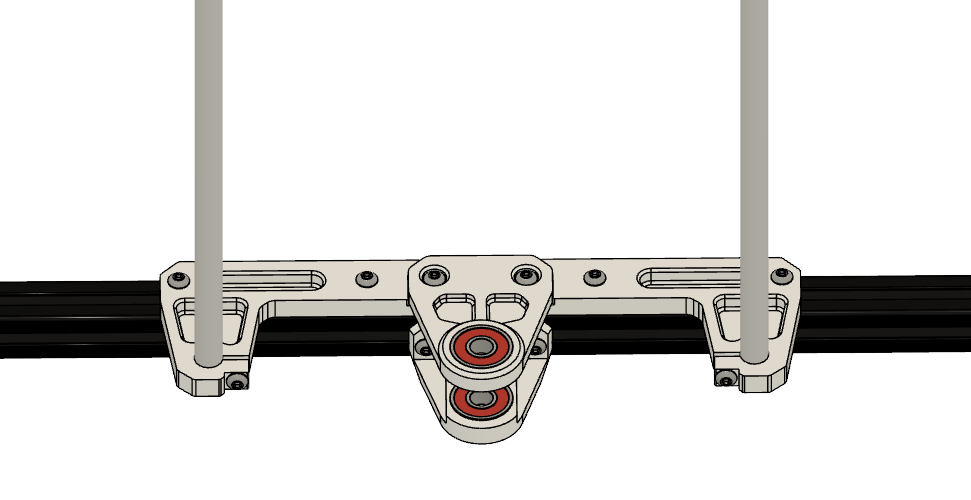

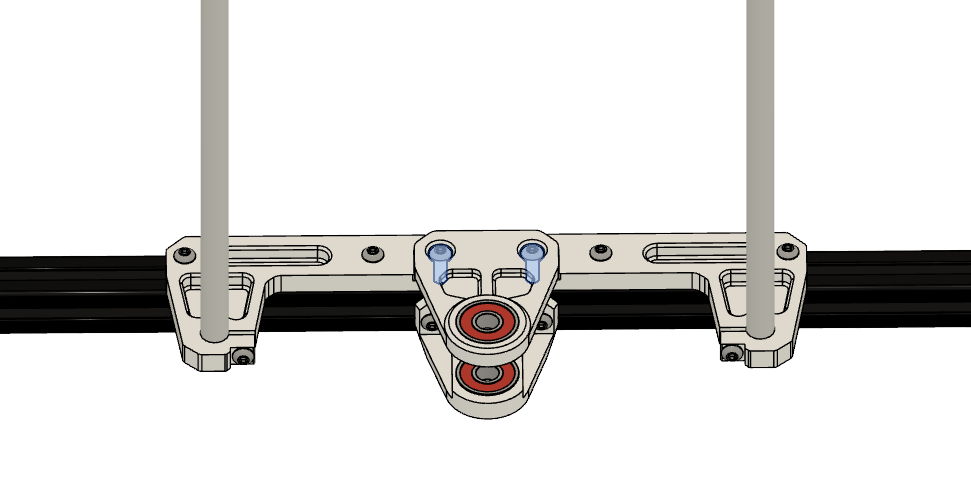

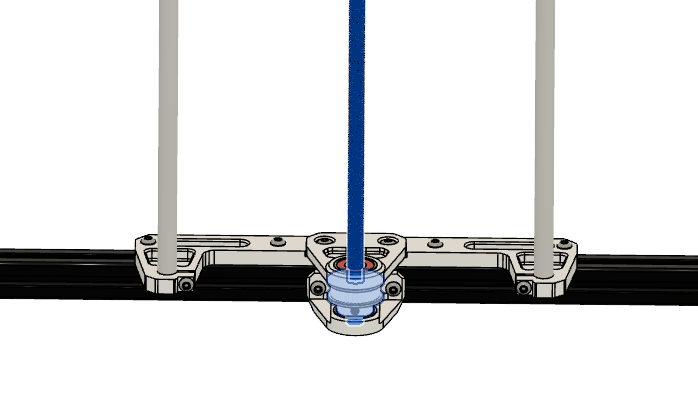

Step 5

Follow these instructions once for each side

Required

• Box 2

|

| Leadscrew Quantity: 2 |

Layer: 2 |

| GT2 40 teeth idler Quantity: 2 |

Layer: 2 Box: VZ330 Box 2 |

| Closed GT2 belt ( 1100mm ) Quantity: 1 |

Layer: 2 Box: VZ330 Box 2 |

|

• Insert closed GT2 belt between lower and upper leadscrew mount • Insert GT2 40 tooth idler between lower and upper leadscrew mount (the beld should be around the idler ) • Insert leadscrew • Secure leadscrew with grub screws of the GT2 idler (leadscrew shouldn’t rub on the ground) • Check that leadscrew is straight and tighten upper and lower leadscrew bracket |